In the dynamic world of freight and logistics, securing cargo is not merely a regulatory requirement—it’s a fundamental aspect of ensuring safety, efficiency, and reliability throughout the transportation process. Among the various tools available for load securing, lashing straps stand out as one of the most versatile, durable, and essential components in the logistics toolkit. From heavy-duty shipping containers to delicate palletized goods, lashing straps provide the stability and peace of mind professionals in the logistics industry rely on every day.

What Are Lashing Straps?

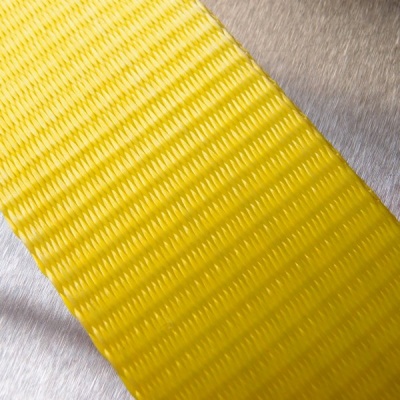

Lashing straps, sometimes referred to as tie-down straps, are flat webbing made typically from high-strength polyester, equipped with buckles, hooks, or other tensioning devices to secure cargo during transportation. These straps come in various widths, lengths, and load capacities, making them suitable for a wide range of applications—from securing small parcels to immobilizing heavy machinery.

Their primary purpose is to prevent cargo from shifting, falling, or getting damaged during transit by trucks, ships, trains, or planes. Unlike chains or ropes, lashing straps provide a combination of flexibility, strength, and ease of handling, which makes them an ideal choice in many transportation settings.

Why Lashing Straps Matter in Freight and Logistics

1. Safety and Compliance

Safety is paramount in logistics, and improper load securing can result in serious accidents, injuries, or costly damage to goods. Lashing straps help ensure that freight is tightly secured, reducing the risk of cargo movement during transit. Many countries enforce strict regulations regarding cargo restraint, and the use of certified lashing straps helps logistics professionals comply with these standards, avoiding fines and legal liability.

In the European Union, for example, the EN 12195-2 standard outlines the requirements for lashing straps used for securing loads on road vehicles. Using certified straps that meet such standards ensures legal compliance and demonstrates a commitment to safety.

2. Versatility in Application

Lashing straps can be used in nearly any freight scenario, making them highly versatile. Whether it’s securing a single pallet on a local delivery truck or anchoring industrial equipment inside a shipping container bound for overseas, these straps can be adapted to the task. They are compatible with a variety of securing points, including anchor rings, rails, and frame holes, allowing for fast and flexible application.

Moreover, lashing straps come with different tensioning mechanisms such as cam buckles and ratchets, providing the right level of control depending on the load type. Cam buckles are ideal for lighter loads that require gentle handling, while ratchet straps are preferred for heavy or dense cargo where a higher tension is needed.

3. Durability and Weather Resistance

Unlike natural fiber ropes or low-grade plastics, high-quality lashing straps are designed to withstand the rigors of constant use and environmental exposure. Polyester webbing is known for its high tensile strength and resistance to abrasion, moisture, UV rays, and chemicals. This makes lashing straps suitable for outdoor applications and long-haul journeys where weather conditions can be unpredictable.

Additionally, lashing straps maintain their integrity even when exposed to heat or cold, unlike materials that may become brittle or stretch excessively in extreme temperatures. This durability ensures that cargo remains secure over long distances and through varied climates.

4. Cost Efficiency

From a financial perspective, investing in lashing straps is a cost-effective solution for cargo securing. They are reusable, lightweight, and easy to store, meaning logistics companies can use them repeatedly without compromising performance. Their relatively low cost, especially when compared to potential cargo damage or fines for improper load securing, makes them a smart and economical choice for businesses of all sizes.

Furthermore, because lashing straps are easy to handle, they reduce loading and unloading times, leading to better efficiency in operations and lower labor costs.

5. Improved Operational Efficiency

Time is a critical factor in logistics, and lashing straps contribute to faster loading and unloading processes. With quick-release mechanisms and adjustable lengths, they allow workers to secure or release cargo rapidly, minimizing delays and keeping transportation schedules on track. Their straightforward design also reduces the need for specialized training, making them accessible for both seasoned workers and new employees.

In high-volume environments such as ports, warehouses, and distribution centers, using lashing straps can significantly streamline operations and reduce turnaround time for trucks and containers.

6. Protection of Cargo Integrity

Maintaining the condition of transported goods is a top priority in logistics. Whether it’s fragile electronics, packaged consumer goods, or industrial equipment, any movement during transit can result in damage, leading to loss, customer dissatisfaction, or return claims.

Lashing straps secure cargo tightly against surfaces or support structures, minimizing vibrations, bumps, and shifts. This protection is especially important when transporting stacked goods or items with unusual shapes, as it ensures even pressure distribution and minimizes stress points.

7. Environmental Benefits

With increasing attention to sustainability in logistics, lashing straps also contribute positively due to their reusability and minimal waste generation. Unlike one-time-use plastic wrap or metal bands, a well-maintained lashing strap can last for hundreds of trips. Some manufacturers also offer recyclable materials and eco-friendly production processes, aligning with green supply chain initiatives.

Choosing the Right Lashing Strap

Not all lashing straps are created equal, and selecting the right strap depends on several factors:

- Load weight and type: Heavier and bulkier cargo will require straps with a higher load capacity and strong ratchet mechanisms.

- Environmental conditions: Consider the temperature, humidity, and exposure to chemicals that the strap will encounter.

- Frequency of use: For daily operations, opt for high-durability, industrial-grade straps that can withstand wear and tear.

- Regulatory compliance: Make sure the straps meet relevant safety standards for the region or mode of transport.

Suppliers often provide technical datasheets or guidance to help logistics professionals match the right product to their needs.

Conclusion

Lashing straps are more than just simple tools for tying down cargo—they are critical enablers of safe, efficient, and professional freight operations. As the logistics industry continues to grow in complexity and volume, the importance of reliable load securing solutions becomes even more apparent. By choosing and using the right lashing straps, logistics professionals can safeguard their cargo, comply with safety standards, and optimize their entire transportation process.

In a world where timely delivery, product integrity, and operational efficiency are key competitive advantages, lashing straps remain an indispensable asset in every logistics arsenal.